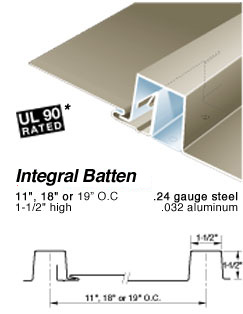

PAC-CLAD Integral Panels are designed for roofing applications, mansards, canopies and fascia. The one-piece design of the Integral Panels minimizes labor and allows for quick and easy installation. Integral panels are to be factory roll formed in continuous lengths (minimum panel length is 4 feet). For roofing applications, a solid underlayment is required.

Standard on-center dimensions are 11", 18" and 19", but for renovation projects or additions, on-center dimensions may be custom matched to your requirements. Neoprene panel closures are available for installation at the eave.

UL 90 Rating

Steel PAC-CLAD Integral Panels carry a UL 90 rating for wind uplift when fastened to an underlayment assembly including 5/8" plywood or OSB laminated to rigid insulation. (UL Construction No. 346 & 347) For further details contact Petersen Aluminum Corp.

Air and Water Infiltration

Petersen Integral Panels meet the full performance requirements of the ASTM E 283 air infiltration test and the ASTM E 331 water penetration test when applied over a solid substrate. For complete test results, contact Petersen Aluminum Corporation.

Materials

a) 24 ga. G-90 hot-dipped galvanized steel b) .032 3105-H14 aluminum or equal

Fasteners

For roofing applications, use Petersen non-penetrating clips. Clips shall be 606l-T6 extruded aluminum, fastened on 18" centers. Use wood-type screws in fastening clips. For fascia and mansard applications, panels should be positively fastened to the substrate.

Trim

All flashing and trim will be fabricated by manufacturer or qualified fabricator. Flashing shall be PAC-CLAD aluminum (.032-.080 gauge as specified) or PAC-CLAD 24 ga. steel. A 20 year warranty shall be supplied covering finish performance.

Installation

Roofing Applications: PAC-CLAD Integral Seam Panels shall be installed over solid decking (5/8" plywood, nailboard insulation or equal) with an underlayment of 30# (min.) roofing felt applied horizontally from eave to ridge. Panels shall be fastened using Petersen non-penetrating clips, fastened on 18" centers (max.). Minimum slope at 3:12 pitch. Consult a local architect/engineer for requirements of local codes and conditions.

| Product Features | |

|

•Herr-Voss

corrective leveled |

|

| Material | |

|

|

•30

standard colors (steel) |

| UL-90 Rating | |

|

•UL

90 rated over solid substrate (steel only) |

|

| ASTM Tests | |

|

•ASTM

E283 tested |

|

|

A complete ManuSpec¿ specification is available on request from Petersen Aluminum Corporation |

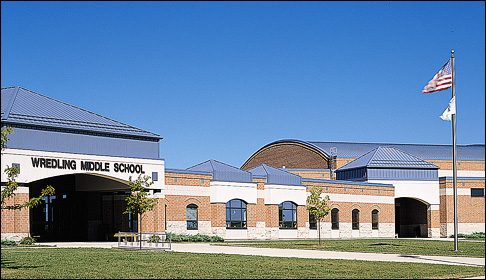

Owner: St. Charles School District

Architect: Hestrup & Associates

General Contractor: E. W. Howell Co., Inc.

Roofing Contractor: Specialty Associates, Inc.

Color: Shadow Gray

*24 ga. panels listed in bold print are UL-90 rated over solid substrate.

Chicago Ridge Village Hall & Police Facility Chicago Ridge, IL

Owner: Village of Chicago Ridge

General Contractor: Elens & Maichin Roofing

Color: Hemlock Green

Profile: Snap-on Standing Seam

Owner: School District of Hudson, WI

Architect: SDS Architects, Inc.

General Contractor: Market & Johnson, Inc.

Sheet Metal Contractor: Innovative Building Concepts, Inc.

Color: Arcadia Green

Profile: Snap-Clad